CNC Manufacturing offers the ultimate in flexibility, high quality and reliable machining services. The high tech facility coupled with knowledgeable and experienced staff provides optimum performance and ability to handle a wide variety of machining requirements. CNC currently supports a variety of customers including industrial, medical and electronics industries. Exotic materials and close tolerance parts are delivered promptly, in both large and small quantities.

(2) Star SR-20R II

(2001)(2004)

- Swiss Type 6 Axis Mill Turn Lathe

- 20 MM spindle capacity

- 10,000 RPM Main and Sub spindle

- 8,000 RPM live tooling (8)

- 6 stationary tools & 8 ID tools

- PC Based Control

- Full C Axis

- Synchronous Tapping

- IEMCA 120 Genius Auto Load bar feeder

(2) Mazak SQT-18MSY/200MSY

(2005) (1997)

- 6 Axis Mill Turn Lathe

- 10 inch chuck

- 4000 RPM 20HP/5000RPM

- 2.5 through spindle

- 6 inch sub spindle

- 4500 RPM live tooling

- Full C Axis

- 4 inch Y Axis Travel

- T-Plus Control/Fusion Control

(2) Star SA-12

(1998)(1999)

- Swiss Type 5 Axis Mill Turn Lathe

- 5/8 inch spindle capacity

- 12000 RPM main Spindle

- 8000 RPM sub spindle

- 6 stationary tools & 8 ID tools

- 3 Live Tools 3000 RPM

- 2 Spego Hydro Bar feeder

- IEMCA 220CH Auto Load bar feeder

(4) Doosan Puma 1800TT

(2018)(2013)(2008)(2008)

- 7 Axis CNC Mill Turn Center

- Two 8 Inch Main Spindles, DL Collets, & Chucks

- 5000 RPM Spindles

- Two 24-Station Turrets

- PC Based Control

- 6000 RPM Live Tools

- LNS Quick Load Bar feeder

- 2.625 through Spindle

- 1000 PSI High Pressure Coolant

(1) Star SB-16

(2005)

- Swiss Type 6 Axis Mill Turn Lathe

- 20 MM spindle capacity

- 10000 RPM main Spindle

- 8000 RPM sub spindle

- 5 stationary tools & 8 ID tools

- 3 Live Tools 5000 RPM

- IEMCA 120 Genius Auto Load bar feeder

(4) Makino Horizontal Mill A51

(2013)(2008)(2008)(2017)

- 6 Axis CNC Mill Center

- Two 400mm Pallets

- 138/60 Tool Changer

- 14000 RPM Spindle

- Auto Pallet Changer

- Laser Auto Tool Measure

- PC Based Control

- Full 4th Axis

- (3) KME 4.5 axis TombStones (2016)

(1) Star SR10J

(2009)

- Swiss Type 6 Axis Mill Turn Lathe

- 3/8 inch Spindle Capacity

- 15000 RPM Main Spindle

- 10000 RPM Sub Spindle

- 6 Stationary Tools & 12 ID Tools

- 7 Live Tools 10000 RPM

- LNS ALPHA 212 Auto Load Bar Feeder

(1) Mazak QT-15 (1995)

- 2 Axis CNC Lathe

- 2.0 Through spindle

- 8 inch chuck

(1) Nakamura-Tome WT-250

(2010)

- 7 Axis CNC Mill Turn Center

- Two 8 Inch Main Spindles, DL Collets, & Chucks

- 5000 RPM Spindles

- Two 24-Station Turrets

- PC Based Control

- 6000 RPM Live Tools

- LNS Quick Load Bar feeder

- 2.625 through Spindle

- 1000 PSI High Pressure Coolant

(1) Nakamura-Tome TW-10

(1999)

- 4 Axis dual spindle lathe

- Two 6 inch chucks & DL collets

- 6000 RPM 10HP

- 1.63 through spindle

- 1000 PSI High Pressure coolant

- Two 12-station turrets

- IEMCA 542 Boss Auto load bar feeder

(1) Tsugami B0326-II Swiss

(2015)

- Swiss Type 7 Axis Mill Turn Lathe

- 1.25 Spindle Capacity

- 8000 RPM Main Spindle

- 10000 RPM Sub Spindle

- 10 Stationary Tools & 14 ID Tools

- 14 Live Tools 6000 RPM

- LNS Express 332 S2 Bar Feeder

- 1000 PSI High Pressure Coolant

(1) Doosan Lynx 220LMSA

(2015)

- 5 Axis Mill Turn Lathe

- Two 6 inch Chucks DL collets

- 2.0 Spindle Capacity

- 6000 RPM Main Spindle

- 6000 RPM Sub Spindle

- One 12 Station Turret

- LNS Express 332 S2 Bar Feeder

- 1000 PSI High Pressure Coolant

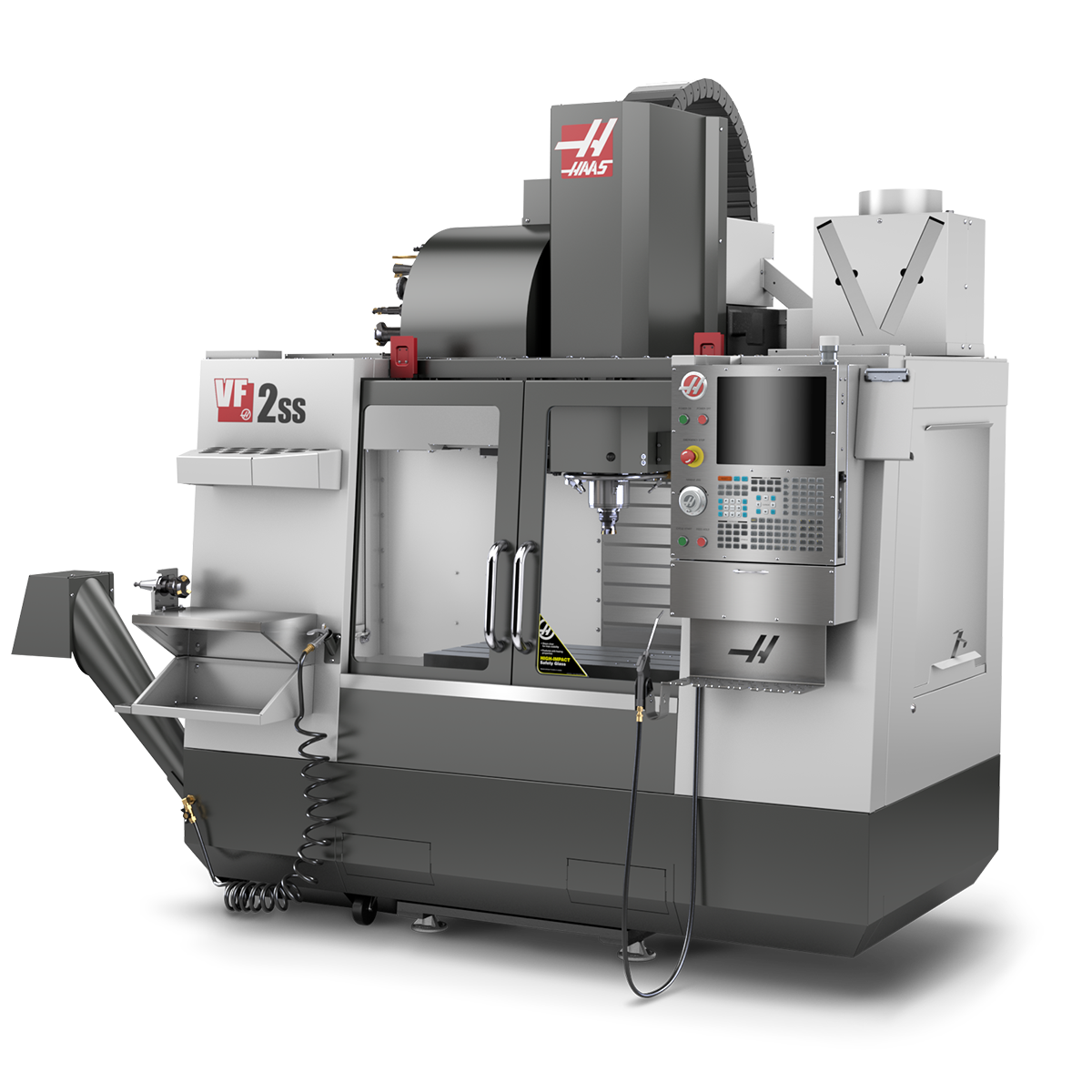

VF-2SS Super-Speed Vertical Machining Center

- 40 Taper

- 3-Axis

- 12,000 RPM

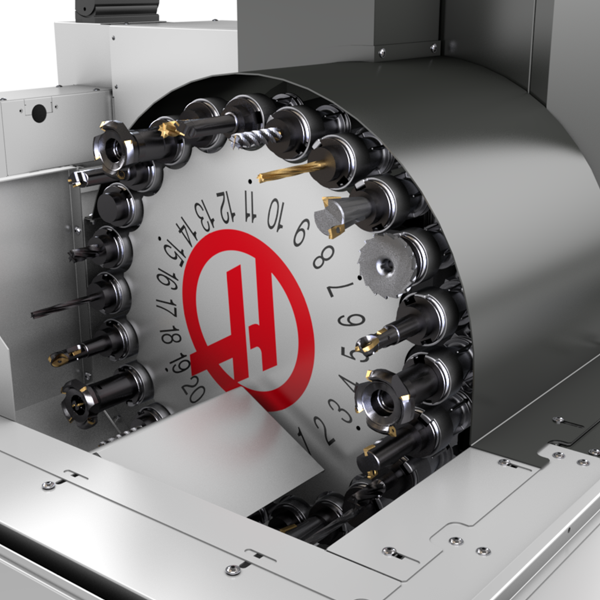

- 30+1 Tool Capacity

- High-Speed Spindle

- Fast Rapids

- Super-Speed Side-Mount Tool Changer

- Made in the USA

CRYSTA-Apex EX 574T PH20 Equipped 5-Axis CNC CMM

- Incorporates PH20 5-axis touch-trigger probe

- Ultra-high speed 5-axis control touch-trigger probe

- Smooth 5-axis control drastically reduces measurement time (typically 40-65%) for probe rotation

- 5-axis design provides highly efficient measurement method of “head touch” for point measurement by moving the probe head only in two axes

Inspection Equipment

- Deltronic DH-216 Optical Comparator (1998)

- OGP Optical Comparator

- Mitutoyo CMM 544 Crysta-Apex C (2006)

- Mitutoyo CMM 574 Microcord (2018)

- Sprint 100 RAM Optical Video Comparator (2005)

- Sprint 250 RAM CMM Optical Video Comparator (2009)

- Mitutoyo MeasurLink SPC SHOP WIDE

Second OP Equipment

- Hartford 190 Thread Roller

- Hardinge DSM

- Spartin Horizontal Saw PA10/3EPC(2005)

- 3 Manual Surface grinders

- Manual Brigeport Miill (1950)

- Manual Sharp Mill (2016)

- K2CNC Bridge Router

- Crest 4 Stage Ultrsonic Cleaner

- Crest Vapor Degreaser

- Sand /Bead Blaster Tumble